🌟Tematys Secures 5 🇪🇺 Horizon Europe Projects🌟

Stay updated with our journey and learn more about our projects:

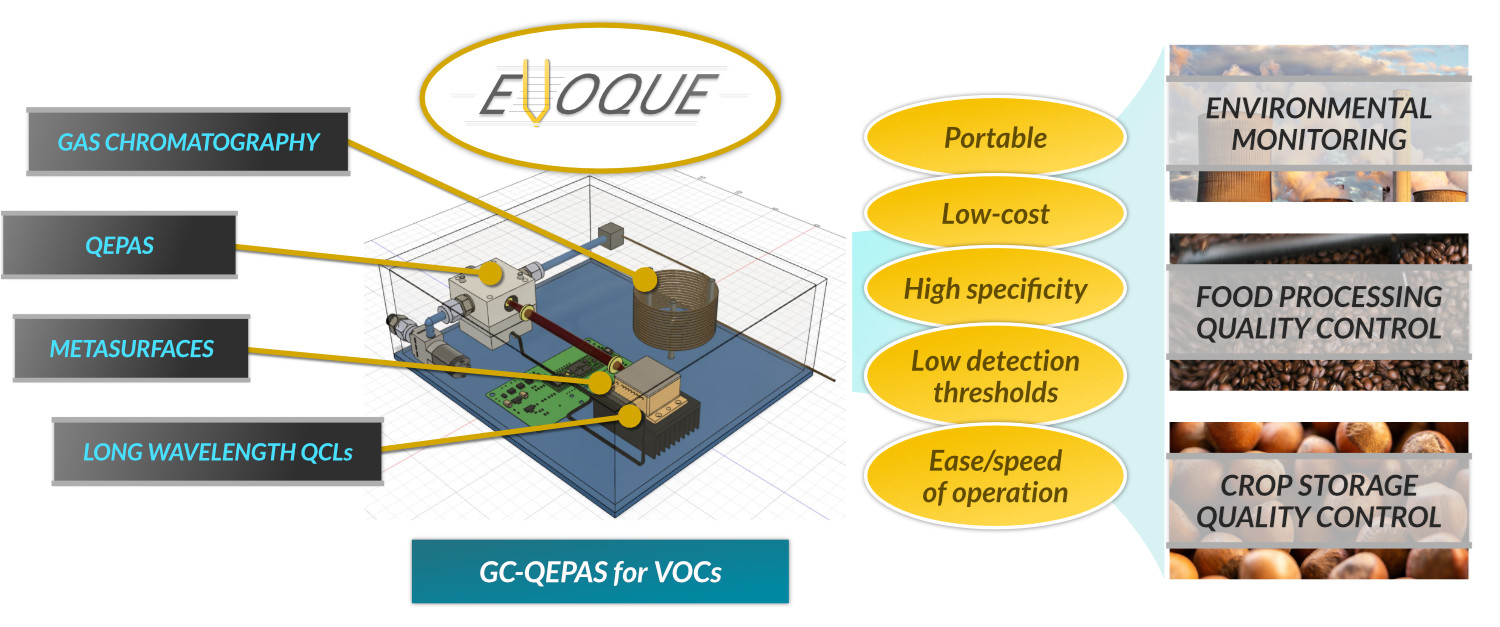

EVOQUE is an EU-funded project whose main objective is to develop a novel photonic-based sensory system with the potential to outperform the current standards and to meet the challenging requirements of at-line, on-line & in-field needs of Agriculture, Food, Environmental Pollution monitoring and Industrial Emissions monitoring.

EVOQUE will combine gas chromatography (GC), Quartz Enhanced Photo-Acoustic Spectroscopy (QEPAS), long wavelength quantum cascade lasers (QCLs) and mid-IR metasurfaces to produce a compact, easy-to-use, low-cost, and ultimately online, field deployable Volatile organic compounds (VOC)s analyser that will have equivalent performance to the gold standard lab-based GC-MS. EVOQUE will leverage GC’s separation of components from complex mixtures, and QEPAS’s high sensitivity, specificity and quantification. Unlike simpler GC detectors, QEPAS will provide molecular recognition based on the specific spectral features of single VOCs. The system measures the target compound even in the presence of interferents, thus avoiding issues with poor repeatability of elution times and reducing the false positive rate relative to GC with non-specific detectors. Also, optical spectroscopy of many VOCs is hampered by absorption by atmospheric compounds at the wavelengths of interest or overlapping absorption features of related molecules; using the GC column, these compounds are separated and eluted from the column at different times, thus unleashing the potential of photonics for sensitive fast, non-destructive measurements of VOCs.

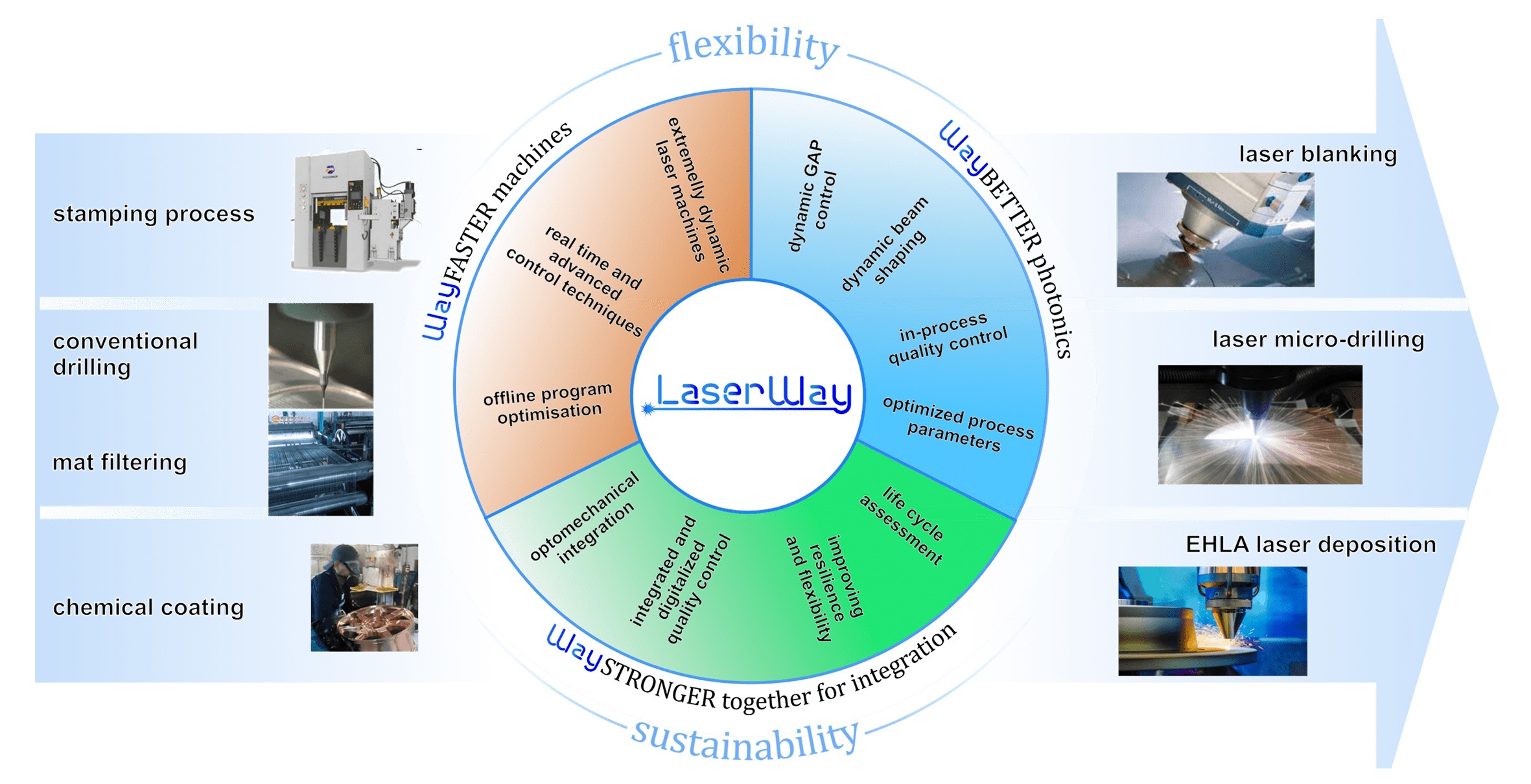

The European manufacturing sector invariably faces the challenge of producing high-quality products whilst operating at elevated production rates. Recent events such as the COVID pandemic and the Ukraine war have increased global uncertainty and prompted European companies to rethink their global supply chain and production methods. Therefore investing in resilient and flexible manufacturing technologies is a must for the future of several European industries.

Nowadays, the manufacturing lines of many sectors are based on rigid processes designed for high-volume production. Laser-based processes can suppose in many cases a flexible alternative for these manufacturing processes. However, laser-based manufacturing processes have not yet exploited all their potential for the industry due to a lack of speed to replace the rigid traditional industrial applications.

LaserWay will revolutionize the manufacturing industry by replacing outdated, inefficient, rigid, and environmentally harmful conventional methods with highly flexible production lines based on high-speed laser technologies. Three high-speed laser technologies will be developed and at least four solutions will be generated to serve the automotive, aerospace, and water filtering industries:

- Laser blanking on moving coil for the production of B-pillars and other BiW (body-in-white) parts.

- Laser micro-drilling to produce perforated airplane wing skins for Hybrid Laminar Flow Control (HLFC) and highly effective and reusable mechanical water filters.

- Extremely High-speed Laser Applications (EHLA) for coating brake discs and repairing large-scale aluminum structural components of airplanes.

While developing its end-goal solutions, LaserWay will also innovate in photonics, machine kinematics for high dynamics, advanced machine control and programming through digital twins, laser delivery control, and on-the-fly high-speed laser process control. Altogether, LaserWay advancements seek to provide pivotal European industries with competitive laser technologies on which they can rely during crises when swift changes on the manufacturing lines might be demanded.

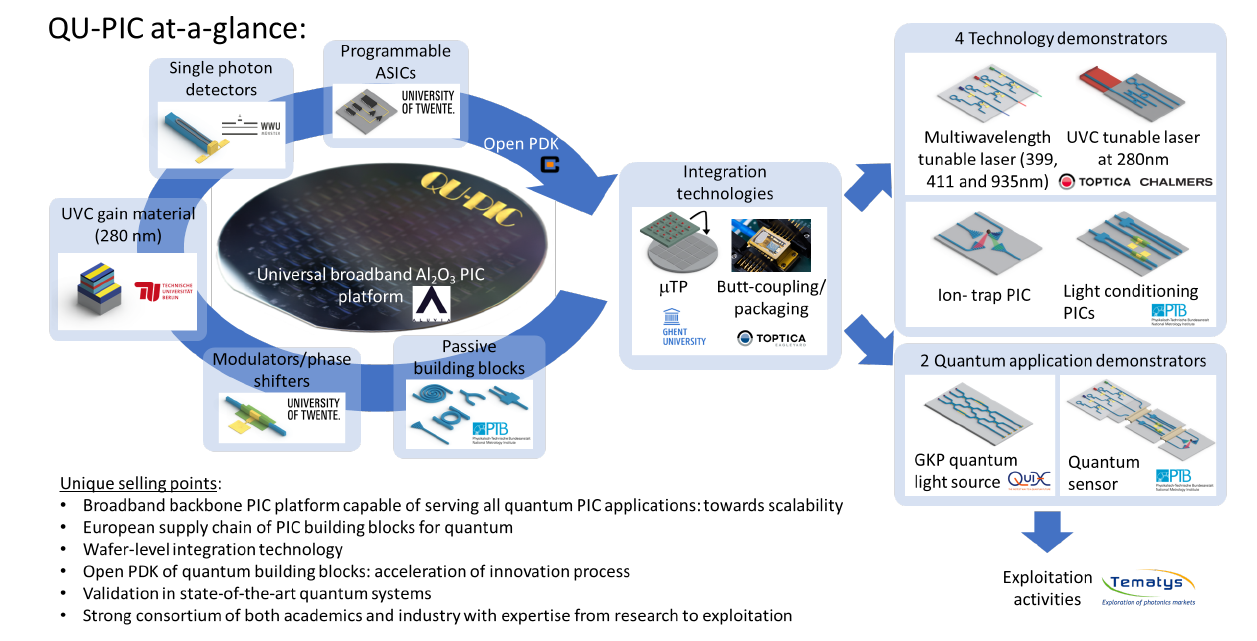

Quantum computers and quantum sensors hold the promise of changing the digital world as we know it. These technologies heavily rely on photonic quantum systems. Currently, most of these systems are based on bulk optics, which imposes a size problem that prevents their scalability. Additionally, these systems lack stability and demand enormous efforts for optical alignment. Therefore, the Quantum Revolution is in the need of smaller, more stable, and scalable quantum systems.

Photonic integrated circuits (PICs) can be the solution to meet the demands of the quantum field and they are starting to be utilized to enable quantum applications. However, each of the reported demonstrations utilizes a different PIC platform. Furthermore, the high propagation losses of this platform together with the limited operating wavelength range (i.e., above 1.1 µm) limit the universality of the PIC technology.

QU-PIC will develop a toolkit of PIC quantum building blocks to accelerate the development of more complex quantum systems, from idea to packaged system. An aluminum oxide (Al2O3) PIC platform will be used thanks to its broad operation spectral window extending from 200 nm in the ultraviolet until the mid-IR. Two main integration technologies will be developed: butt-coupling of gain sections to Al2O3 PICs and micro-transfer printing (µTP). Finally, two demonstrators with relevant quantum applications will be produced: a GKP (Gottesman-Kitaev-Preskill) quantum light source and a quantum sensor.

With the expected QU-PIC’s technological advancements, many of the technologies required in the supply chain for quantum systems will be developed to ensure its availability in Europe, which is key to establish European sovereignty in the emerging quantum field.

A Game-Changer in Photonic-Based Sensory Systems

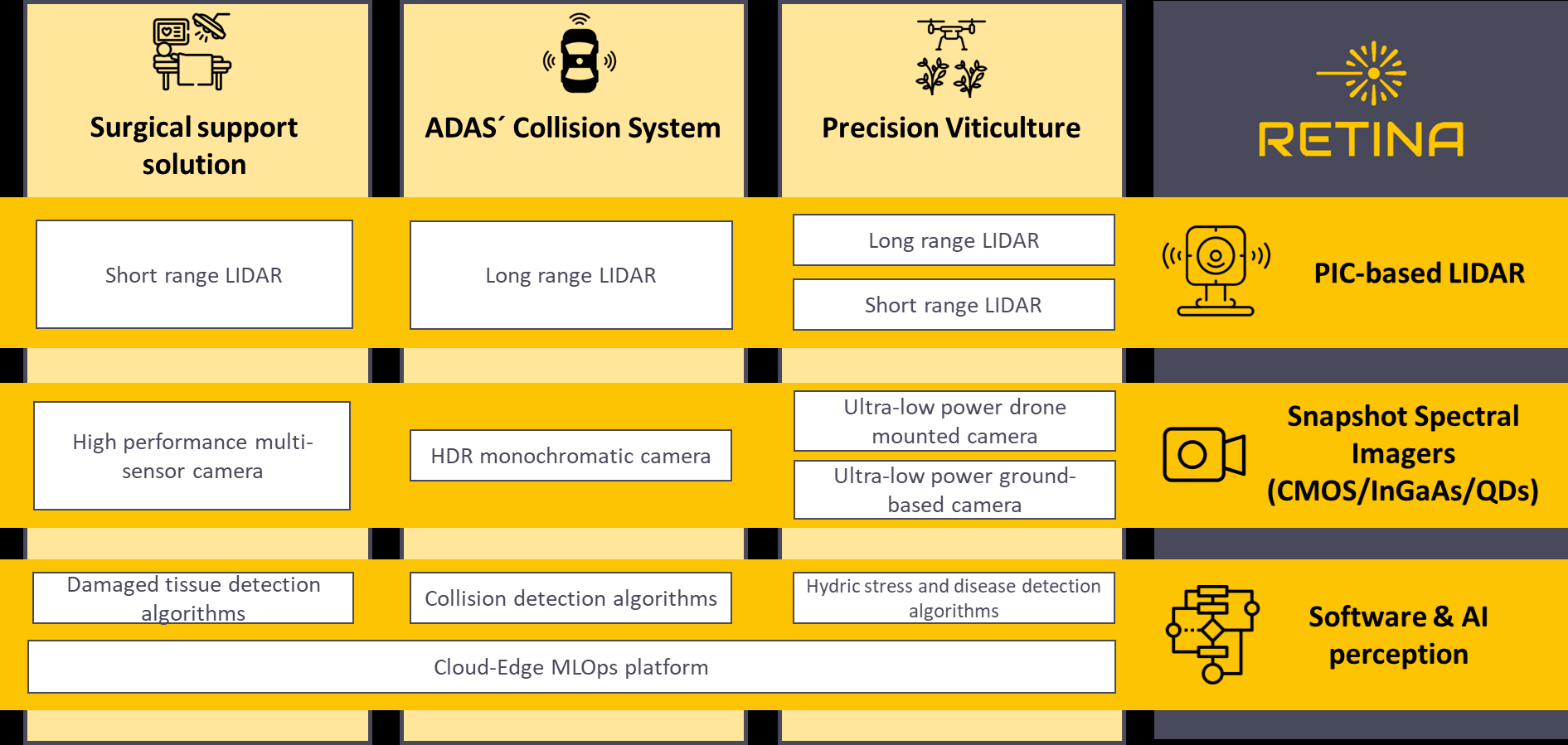

At RETINA, we are pioneering the frontier of photonics with our latest venture – a groundbreaking project set to revolutionize the healthcare, automotive, and agriculture industries. Our focus? Developing two innovative photonic-based sensory systems, integrating advanced hardware and software solutions to meet and exceed the dynamic needs of these key sectors.

Our holistic approach in photonic technology development encompasses next-generation hardware solutions. This includes a novel PIC-based LIDAR solution and cost-efficient CMOS, InGaAs, and QDs snapshot spectral imagers. But that’s not all – we’re also creating a digital infrastructure for agile and efficient Machine Learning-based perception algorithms.

Enhancing surgical precision with our technology, enabling the identification of tumorous cells and blood perfusion monitoring. This leap in medical imaging and diagnostics represents a significant advancement in patient care and surgical outcomes.

Driving the future with advanced ADAS vehicle collision detection systems for autonomous driving. Our technology promises to enhance safety and reliability, pushing the boundaries of what’s possible in vehicle automation and road safety.

Revolutionizing precision viticulture with solutions for hydric status management and predicting pathogen infections. By providing accurate and timely data, we empower farmers to make informed decisions, optimizing crop health and productivity.

Our sensory systems, based on cutting-edge photonic technologies, are not just innovations; they are the driving force for change across diverse industries. From disease detection in healthcare to advanced mobility and infrastructure surveillance, RETINA is setting a new standard in technological advancements.

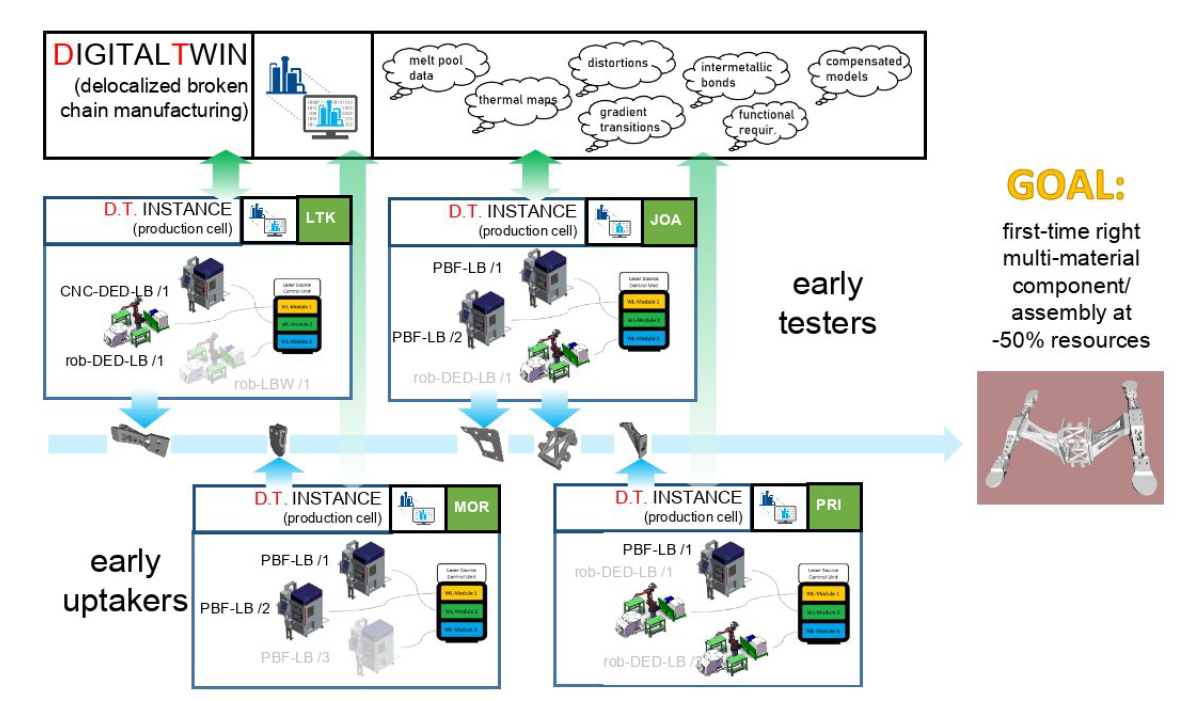

WAVETAILOR focuses on two industrial scenarios which are related to the complex multi-material components and assembly. The first one is the Directed Energy Deposition of a multimaterial leading edge for a hypersonic hydrogen-driven airplane, while the second relates to the Powder Bed Fusion of complex multi-material assembly of a drone for urban delivery. The challenges in both cases are related to zero-defect manufacturing, sustainability and first-time-right manufacturing. WAVETAILOR aims to solve the high-precision in complex material structure manufacturing, the disassembly, reuse and recycling of components while reducing the environmental footprint of both the manufacturing process and the components themselves.

To achieve this, three main pillars are developed in the project: 1) flexible energy-efficient photonic setup based on modular diode-based laser source and multi-wavelength optics; 2) full reconfigurability of this setup, to use minimal energy and material resources in the manufacturing of two use cases and 3) ZDM and ZDW strategies at assembly level, controlling the compliability of complex multimaterial products at the machine level, shop floor level, and delocalized manufacturing chain level. The latter pillar will be based on digital sibling (shop floor level) and twin (cloud level) for automatic assessment of component/assembly design for circularity; first-time-right process planning using synthetic legacy data and ZDM/ZDW based on real-time process and post-process monitoring.

When the WAVETAILOR objectives are achieved, the manufacturing process of the two use cases will have spent 200 MWh of energy less, 923 kg of waste less, while the production costs are going to be 50-65% lower. In order to prove this, a dedicated sustainability study is provided along the project.

Stay tuned for more updates as we make strides in these exciting ventures! 🌟

Visit our website 🔗 to find out about our ongoing and past projects.

What makes consortia choose us?

- We actively participate in Writing proposals – specially focussing on impact and business cases

- We provide Business & Market Data

- We produce in-depth market and technology analysis on various topics in Optics, Photonics, Sensing, and Quantum

- We have a well-established Exploitation methodology for EU projects

- We handle Dissemination & Communication activities: Website, Social Media, and management of other involved tools